Mechanical testing and microstructural examination of materials provide necessary data for material selection and modelling material performance during the preliminary and the final design stages, verifying materials in accordance with the specifications before manufacturing and maintenance operations. Ion can provide standard and non-standard tests and examinations of both metal and some non-metal specimens or components. The typical ones are as follows:

To receive a technical and price quotation, please complete our request form and submit it via email to hafize.cakmak@ion-metal.com

MATERIAL TESTING AND CHARACTERIZATION

Ion Metal owns the sole independent NADCAP material testing laboratory in Turkey. In addition to the conventional ones, sophisticated material tests such as load/strain controlled fatigue, fatigue crack propagation, fracture toughness and creep-rupture tests at varying temperatures and environments as well as microstructural examinations using microscopes, are within the scope of the laboratory’s accreditation. Test methods within Ion’s capabilities are detailed in the following paragraphs. Being aware that one of the most important conditions of obtaining a precise test result is specimen preparation, Ion Metal prepares all test specimens with its own infrastructure and within the scope of its accreditation as well.

TESTING SYSTEM DESIGN, INTEGRATION AND VERIFICATION

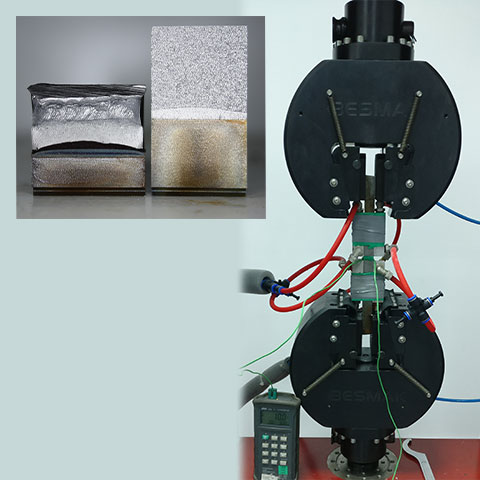

Selection and manufacture of the mechanism and components of the system appropriately for the test environment requires specific knowledge and expertise. Ion can design and integrate custom systems for specimen and component performance tests introducing multiaxial loads at varying environmental conditions. Ion also designed and delivered the first national creep and stress-rupture testing frame to laboratories. In addition to testing systems, Ion has also developed and integrated a CNC-based polishing device that reduces the surface roughness and residual stresses of fatigue test specimens. The analogs of this particular specimen preparation device are very limited in the world. Developed with Ion engineering, this device is qualified according to the requirements in ASTM E466 and E606 annexes and Nadcap audit criteria.

| MECHANICAL TESTING | METALLOGRAPHY | ||

| Tensile tests | ASTM E8 & E21, ISO 6892-1, -2, -3 | General Metallography | |

| Compression tests | ASTM E9 | Grain Size Determination | ASTM E112 |

| Bearing test | ASTM E238 | Inclusion and Porosity Rating | ASTM E45 |

| Creep, creep-rupture, stress-rupture tests | ASTM E139 & E292, ISO 204 | Macro-etch Examination | ASTM E340 |

| Fracture toughness and resistance to fracture (R-curve) tests | ASTM E399, E1820 & E561, BS 7448-4 & 8571, DNV GL RP-F108, ISO 12135, 12737 & 15653 | ||

| Strain and load controlled fatigue (LCF & HCF) and crack propagation tests | ASTM E466, E606, E647, ISO 1099, 12106, 12108 | SPECIMEN PREPARATION | |

| Hardness tests | ASTM E10, E92 & E384, ISO 6507-1, 9015-1 & -2. | Standard Specimen Preparation, Z | ASTM, ISO |

| Charpy Impact Test | ASTM E23, ISO 148-1 | Low-stress Specimen Preparation, Z2 | ASTM, ISO |

| Bending Test | ISO 7438, 5173 | Special Specimen Preparation (weldment etc.), Z3 | ASTM, ISO |

| Welding Procedure Qualification Tests | ASTM, API, ASME, BS, DNV GL, ISO | ||

| Slip Factor Determination | EN 1090 | ||

TENSION TEST

Tensile testing provides information on the strength, stiffness and ductility of materials under uniaxial and and quasi-static monotonic tensile loading, which is obtained using a displacement controlled testing units. Extensometers with gauge lengths equal to or shorter than the nominal gauge length of the specimen are generally used to determine the strain during the test. Electro-mechanical and servo-hydraulic universal testing units with proper force sensors, extensometers for measuring the strain of specimen under loading, and proper dimension-measuring devices are available in our laboratory. Ion can provide the testing at cryogenic and elevated temperatures, as well as at the room temperature.

COMPRESSION TEST

The strength and ductility properties under compressive loads are of interest in the analyses of structures that subject to compressive forces and/or bending moments and in the analyses of metal working that involve compressive deformation such as forging and rolling. In the case of a material does not fail by a shattering fracture, compressive strength is a value that depends on total strain and specimen geometry.

CREEP & STRESS RUPTURE TESTS

Creep and stress rupture testing methods are for characterization of deformation amount as a function of time (creep test) and measurement of the time for fracture to occur when sufficient force is present (rupture test) for materials under constant tensile forces at elevated temperature. Dead-weight testing frames and electro-mechanic testing units with proper heaters and linear variable displacement transducers for measuring the strain of specimen under loading are available in our laboratory.

HARDNESS TEST

Determining the hardness of a material enables one to assess its strength, ductility, wear resistance etc. It is a test to determine the resistance that a material exhibits to permanent deformation by penetration of another harder material. Hardness is not a fundamental material property, therefore any hardness value should be reported in relation to the given load on the indenter, loading duration and the indenter geometry. Hardness testing is divided into two ranges with respect to the load applied and methodology. The applied load is greater than 1 kg in macrohardness examinations, such as Vickers, Brinell and Rockwell. This testing is usually employed to determine whether a material treatment is suitable for the service. Whereas microhardness is used for characterization of specific microstructures. Vickers and Knoop are conventional microhardness test methods where hardness values are determined by optically analyzing the indented impression. Unlike these conventional methods, Berkovich indentation uses a three-sided pyramidal indenter, which is theoretically designed to an atomic point at the tip.

CHARPY IMPACT TOUGHNESS TEST

The integral of stress vs strain curve that is produced from a uniaxial tensile test is a measure of material toughness under quasi-static loading conditions. When measure of the material’s toughness in the presence of brittle fracture due to a higher triaxiality, or strain rate, and/or a lower temperature is a concern, then Izod or Charpy impact tests can provide such information. These tests are performed using specimens with a notch that is located at a specific microstructures, like fusion or heat affected zones of weldments and application of impact loads.

FRACTURE TOUGHNESS & RESISTANCE CURVE TESTS

Ion provides fracture toughness tests of metallic materials by means of K, CTOD (δ) and J-integral for homogenous metallic materials or their specific microstructures subjected to quasistatic and Mode I loading. Fracture instability results in a single point-value of fracture toughness determined at the point of instability. Whereas stable tearing results in a continuous fracture toughness versus crack-extension relationship (R-curve) from which significant point-values may be determined. Stable tearing interrupted by fracture instability results in an R-curve up to the point of instability. Our laboratory is capable of working with all types of specimens such as single edge notched bending, single edge notched tension and all derivatives of compact tension specimens. Post-test quantitative fractography and metallography are complementary procedures that our laboratory is capable of as well.

LOAD / STRAIN CONTROLLED (HIGH / LOW CYCLE) FATIGUE & CRACK PROPAGATION TESTS

Fatigue tests are used to demonstrate crack initiation and propagation behavior of a material that is susceptible to cyclic loading. Testing of specimens can also be carried out in a conditioner chamber where the temperature or composition of the atmosphere is controlled to investigate the assistance of environment to cracking. Besides a travelling optical microscope, extensometers or displacement gauges can also be used to measure the crack extension by time. Strain gauges are useful to monitor the strain of stress field around the crack tip.

BEARING TEST

This test method covers a pin-type bearing test of metallic materials to determine bearing strength parameters. Such parameters are useful in the comparison of materials and design of structures under conditions where the pin is not restricted.

WELDING PROCEDURE QUALIFICATION TESTS

Welding procedures are qualified by welding procedure tests. The typical mechanical tests are transverse tensile test, bend test and macro-etch examination after non-destructive tests, such as visual examination, magnetic particle or liquid penetrant testing for surface imperfections and ultrasonography or radiography based testing / inspection methods. According to the assessment criteria and the service environment, additional mechanical testing may be required such as impact toughness, fracture toughness, wear or corrosion tests. Ion can provide almost all standard tests to confirm the integrity of production or repair or built-up welds.

TESTING OF BOLTED CONNECTIONS

Slip-critical steel joints with preloaded bolts should exhibit high rigidity against fatigue and vibrational phenomena. The most important parameter for the calculation of the bolt number and its class in a friction connection is the slip factor. The purpose of this test is to determine the slip factor for a particular surface treatment. The slip testing of a particular surface treatment of a bolted structural steelwork components is conducted under uniaxial and quasi-static monotonic tensile loading and measurement of pre-load on the bolts that is evolved during torqueing and testing. The preload in the bolts is directly measured with strain gauges. The test procedure is intended to ensure that account is taken of the possibility of creep deformation of the connection.

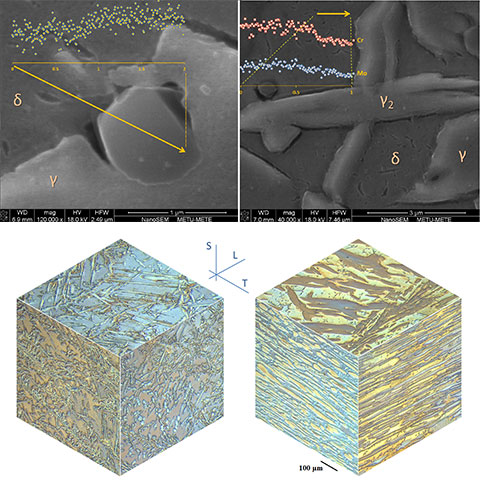

METALLOGRAPHY & FRACTOGRAPHY

Metallography is the effort for qualitative and quantitative investigations of physical structure of metals. When ceramics and polymeric materials are subjected to such microstructural examinations, the term may become ceramography and plastography, respectively, or collectively materialography. Crystallography steps in the investigation when more detailed phase or texture information is required. Fractography, which is examination of fracture surfaces, is used the determine the cracking mechanisms involved to any material failure. They all may be applied to a material for condition or damage assessment purposes, of for validation of a treatment or testing. Ion has access to optical and electron microscopes that are equipped with EDX and EBSD interfaces.